One room to produce various radiopharmaceuticals

One room to produce various radiopharmaceuticals

The radiochemistry iMiLAB is compact and self-shielded. Entirely robotized and GMP compliant, the radiochemistry room utilizes microfluidic techniques capable of producing diversified radiopharmaceuticals in an automated synthsizer and cartridges with precursors and solvents. It is capable of synthetizing multiple radiopharmaceuticals on a same-day.

Fully Automated Operation

- Process entirely automated

- Robotized radiochemistry room with a 6-axis robot

- Ready-to-use syringes

iMiLAB is designed for fully automated operation from radiopharmaceutical selection to sterile filter integrity test and syringe-filling. It is equipped with a 6-axis robot, programmed on the intuitive user interface to operate the entire system, after the microfluidic cartridge has been prepared with the adequate precursors and solvents. At the end of the synthesis process, ready-to-use syringes are made available to the radiopharmacist : one for the patient and one for QC, with precise radioactivity measurements.

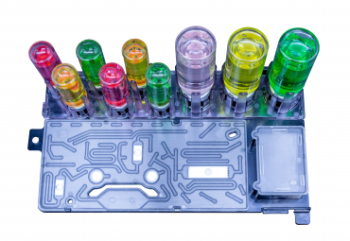

Microfluidic Technology

- Low reagent and precursor consumption

- Faster reaction rate even at lower temperature

- Fully integrates valves, channels, reaction chamber and SPE chambers minimizing dead volumes

- Completely closed consumable preventing contamination

The synthesis process is mainly carried out in an innovative radiosynthesis box using a unique microfluidic cartridge. Due to its architecture, iMiLAB can produce multiple radiopharmaceuticals based on 18F, 11C, 68Ga, within the same day (list of radiotracers). Single-use cartridges prevent cross contamination. Thanks to microfluidic technologies, reagent and precursor consumption is low, synthesis is quick and the parameters are better controlled.

Facilitated Use and Maintenance

- Easy-to-use

- Minimum need in staff

- Low level of radioactivity

- Easy-to-maintenance

Due to its intuitive interface iMiLAB is easy-to-use. The operator has all the required information depending on their expertise and training levels. The user manages the production from the control room.

Because iMiLAB is designed for fully automated operation, its use requires only few personnel and the staff is exposed to a lower level of radioactivity.

Moreover, the equipment inside the production room is easily accessible for maintenance operations.